SERVICES

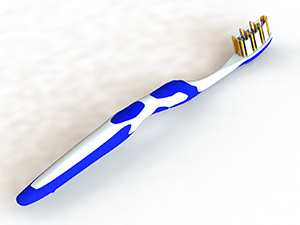

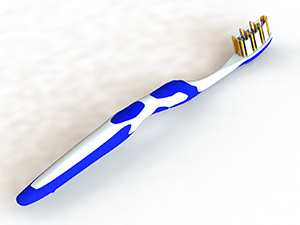

The art of reinventing

the toothbrush – time and time again.

again

We develop intelligent, tailored solutions for customers, from market analysis to market introduction. Outstanding customer service and technological edge have made us an innovation leader, and one of the most successful companies in the sector.

360° customer service

Full-service solution provider –

our complete solution

Full-service overview

We see ourselves as a system partner and offer complete solutions – from the initial idea, through design, prototyping, market research, clinical tests and series production, to on-time delivery. Every project is overseen by your contact partner.

Ideation & Consultation

We are experienced and know the market. Competencies our employees use to develop innovative product ideas for you.

Market research

Working with well-known partners, we check whether future products meet market and target-group demands. Global trend analyses ensure early detection of successful new product ideas.

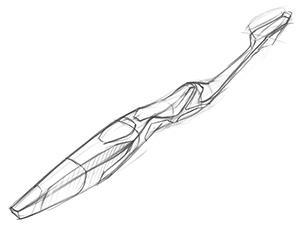

Product development and design

Working with major industrial design agencies and renowned scientists, we continuously develop the shape and function of toothbrushes, and in doing so draw up individual product solutions for each customer.

Rapid Prototyping

We take the quickest and most efficient route from idea to series production, supported by in-house prototyping in our own R&D department, and work with pilot molds from our own prototype workshop. This reduces development costs and time to market.

Production

Modern and efficient manufacturing processes ensure optimum mass production. Our fully automated production lines guarantee the highest hygiene and quality standards (‘no human touch’).

Packaging & POS

Appropriate market and target-group packaging is crucial for sales. We develop successful concepts for attractive, user-friendly packaging.

Delivery and logistics

Working with our long-term logistics partners, we deliver products globally, quickly and on-time.

We see ourselves as a system partner and offer complete solutions – from the initial idea, through design, prototyping, market research, clinical tests and series production, to on-time delivery. Every project is overseen by your contact partner.

We are experienced and know the market. Competencies our employees use to develop innovative product ideas for you.

Working with well-known partners, we check whether future products meet market and target-group demands. Global trend analyses ensure early detection of successful new product ideas.

Working with major industrial design agencies and renowned scientists, we continuously develop the shape and function of toothbrushes, and in doing so draw up individual product solutions for each customer.

We take the quickest and most efficient route from idea to series production, supported by in-house prototyping in our own R&D department, and work with pilot molds from our own prototype workshop. This reduces development costs and time to market.

Modern and efficient manufacturing processes ensure optimum mass production. Our fully automated production lines guarantee the highest hygiene and quality standards (‘no human touch’).

Appropriate market and target-group packaging is crucial for sales. We develop successful concepts for attractive, user-friendly packaging.

Working with our long-term logistics partners, we deliver products globally, quickly and on-time.

Technological edge– we

make it possible

The Schiffer Group is the leading innovator in the sector. To take just one example: the in-mold technology we developed and patented, which produces complete toothbrushes in one uninterrupted production step.

It is efficient, hygienic and offers unlimited design freedom. It also opens new perspectives for brush head geometry, functionality and clinical claims. Special filaments, flexible brush heads as well as the world’s most compact brush-head dimensions are only possible thanks to Schiffer’s in-mold technology. These cutting-edge technologies have made us a global Best-in-Class Partner who successfully completes even the most complex projects around the world.

„Understanding customers, knowing the

market and using technologies intelligently

are the foundation of

optimal solutions.“

High-tech production

The Schiffer Group has one of the most state-of-the-art toothbrush manufacturing plants in the world. We handle large-scale production efficiently and reliably on fully automated lines – from plastic granules to the finished product. Thanks to production with ‘no human touch’, our products meet the most stringent hygiene requirements. The modular structure of our manufacturing systems also means we can respond to individual customer requests and offer customised products. We manufacture ‘just-in-time’ in accordance with the tried and tested Kanban method. This makes it easy to integrate inventories, special packaging or promotions.

Perfection goes into production

We take perfection personally.

We at the Schiffer Group believe you need the best internal and external processes in order to produce the world’s best toothbrushes. We therefore guarantee each customer a dedicated contact partner who oversees their projects – from the initial idea to the finished product. This creates trust and ensures your success.

Quality assurance – leaving nothing to chance

From goods receipt to dispatch, all products are subject to uninterrupted monitoring. Trained employees and highly sensitive inline cameras use in-process controls to check and document product quality on a continuous basis. Product coding as well as electronic recording of the parts used ensure complete traceability – even years later. And we conduct all the necessary mechanical checks ourselves using state-of-the-art testing and measuring equipment. All Schiffer Group sites work to the same standardised quality-management system and are of course certified to ISO 9001 and BRC CP3.

Our head office in Germany is also audited to ISO 14001 and ISO 50001. We are members of BSCI and SEDEX. Our site in India is also certified to the important social accountability standard SA 8000.

Outstanding product designs and production technologies

R&D is the core of our business and the guarantor of our success. We work with the most prestigious design agencies and scientific institutions so that our customers can offer the best products. And we adopt a proactive approach to developing new technologies and production facilities. As a family company, we can make quick, independent decisions. We put special emphasis on the rapid market readiness of our products, supported by state-of-the-art technologies such as rapid prototyping, and by the work with pilot molds in our prototype workshop. This reduces development costs and time to market for our customers. We can even develop entire product families in a very short time frame.

Specialist engineering – customised solutions, customised products

Our head office in Germany is also audited to ISO 14001 and ISO 50001. We are members of BSCI and SEDEX. Our site in India is also certified to the important social accountability standard SA 8000.